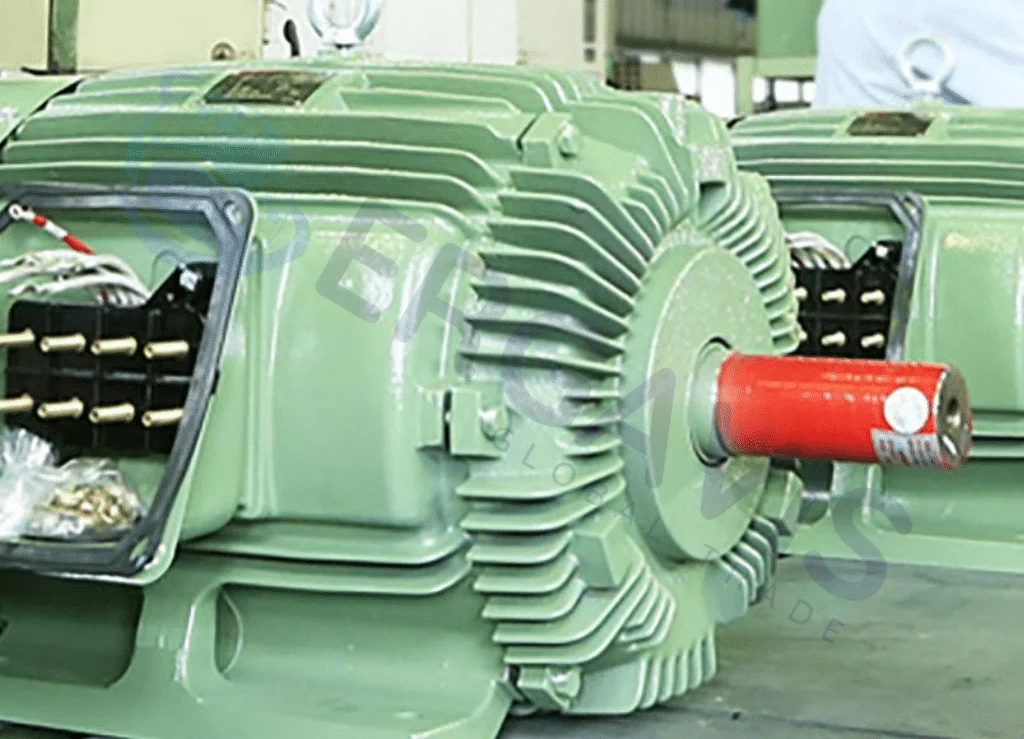

Three-phase induction motor: After the motor is supplied with three-phase alternating current in the stator winding, a rotating magnetic field will be generated. The closed guide bar on the rotor will cut the magnetic force lines of the rotor, inducing the potential and current in the stator magnetic field and the passing conductor will be in the magnetic field and subjected to the Ampere force, which will drive the rotor to move. The horsepower of three phase induction motor is more than 1/4HP and can reach 270HP. It is divided into 2P, 4P, 6P, 8P and other poles.

Electric Motors

Origin: Taiwan

From the best electric vehicle power system and industrial motor technology and manufacturing service provider in Asia, you can meet all your motor needs at competitive prices.

Electric Motor Products

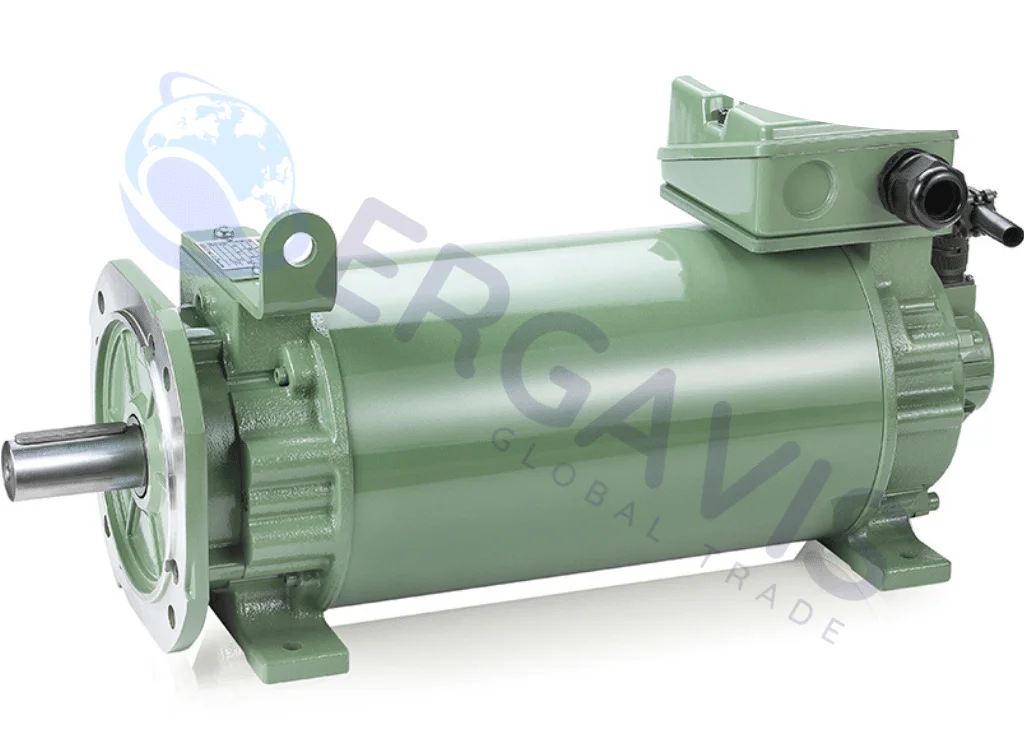

The motor designed for the inverter is a special inverter motor developed from the traditional squirrel cage motor. The cooling fan of the traditional squirrel cage motor is driven by the motor, and the variable frequency motor uses a forced fan with an independent power supply to avoid the problem of poor heat dissipation caused by the slow fan speed when the motor is at low speed, and to improve the insulation performance of the motor winding The motor is also equipped with a rotary encoder as feedback for speed or position.

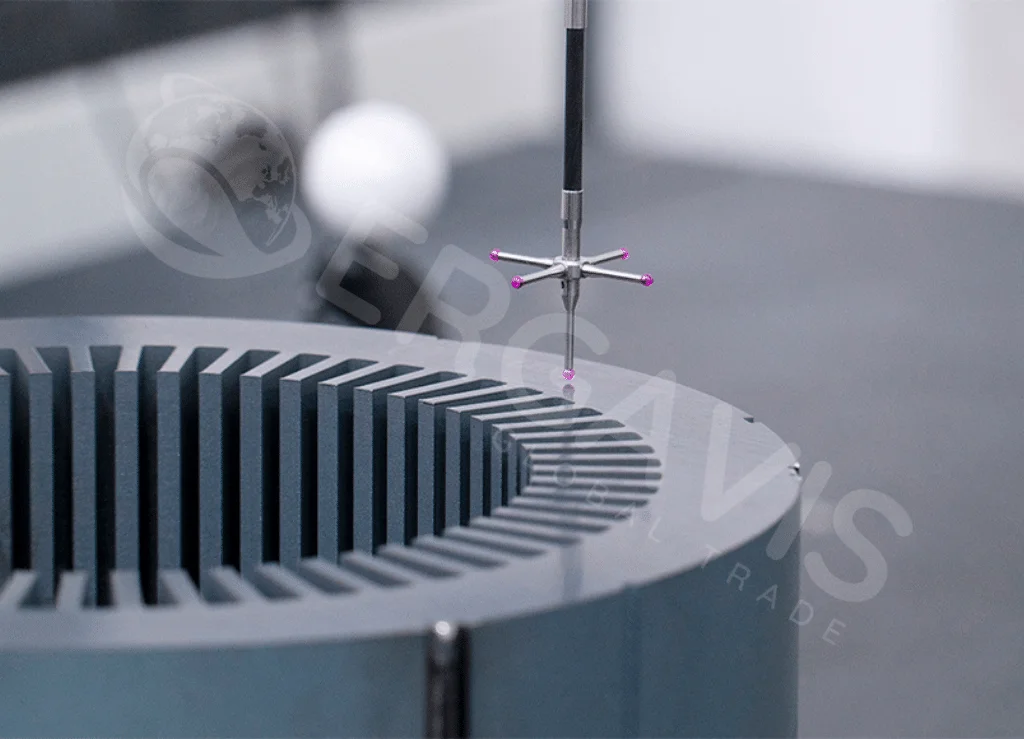

The transmission characteristics and energy-saving efficiency required by various industrial machinery cooperate with sound R&D and designs to jointly enhance competitiveness. Inspection equipment for such products can spare no effort to invest more time and manpower to ensure the stability of the quality of each product produced; a complete marketing and design team can better meet the needs of various countries.

A permanent magnet synchronous servo motor is a servo motor that uses permanent magnets, and is further divided into SPM (surface permanent magnet synchronous motor) and IPM (internal permanent magnet synchronous motor). The type of synchronous servo produced is SPM. The structure of the surface type permanent magnet motor is simple. The magnet is glued or fixed on the rotor surface.

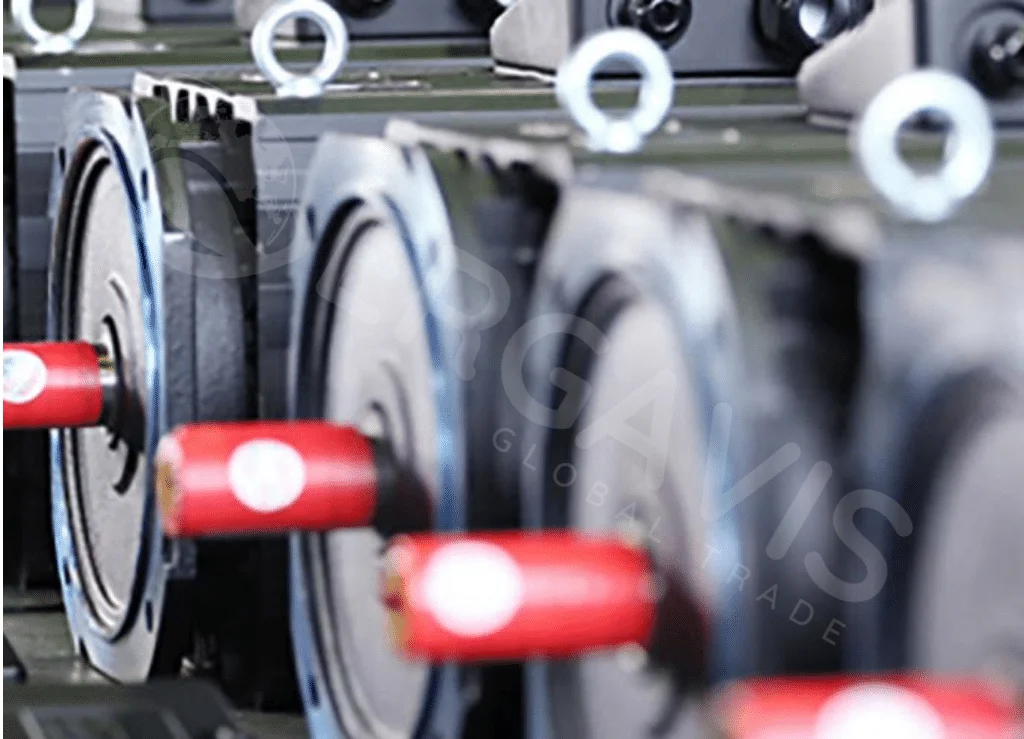

Asynchronous servo motor is also called frequency conversion servo motor. Its appearance is divided into aluminum frame and multi-chip type. It can be used together with encoder for speed detection to achieve closed-loop control. It cannot be operated directly. It needs to be powered by mains power and an inverter.

The liquid-cooled servo motor is suitable for harsh environments with a lot of water, oil, dust and high ambient temperature. The oil cooling or pure water system is cooled by water circulation heat exchange. The motor uses an induction servo. The construction eliminates the need for forced trouble with fan damage, replacement/fixed maintenance.

The special structure design can maintain inherent operating precision and electrical characteristics even at extremely high speeds, which meets the electrical and mechanical requirements of CNC machines.

In order to provide better service, motor base and rotor stator are produced to meet customers’ product diversity needs. For special motor accents, the team should be contacted.

Application Areas

Over the years, the most professional OEM services have been provided to electric vehicle customers in the US and Japan. Motors for electric cars, electric trucks, electric buses, 3-wheelers, motorcycles are produced. Customized production is also available. You can contact us for detailed information.

Whether it is electric boats, ski cars or agricultural construction machinery, etc., the company has the experience to customize tailor-made electric vehicle solutions for customers to increase product uniqueness and brand competitiveness in the market. You can contact us for customizations.

A wide range of products such as extrusion machines, blown bag machines, special shaped extrusion machines, hollow mold machines, plastic pellet recycling machines are produced. The temperature will not rise too much in the developed engine. The product is lightweight. You can contact us for detailed information.

Taiwan’s woodworking machinery can be divided into two main product categories. One is DIY, which is used for woodworking equipment for schools, simple manufacturing and maintenance; the other is used for furniture manufacturing and woodworking. It has international certifications such as CE, CSA and UL.

Conventional motors, frequency conversion motors and servo motors with stable torque output and low vibration processes have been developed for grinding machines, lathes and milling machines. You can contact us for detailed information.

Special motors have been developed for water pumps. The fully enclosed structure can reach IP54, IP55 dustproof and waterproof grades, resistant to heat and humidity, resistant to resistant chemicals. It can be applied in various environments.

The motors are widely used in: blowers, high pressure fans, water washing hoods, centrifugal fans, axial fans, cooling fans for cooling water towers and fans used in highly polluted or corrosive environments. Contact for more info.

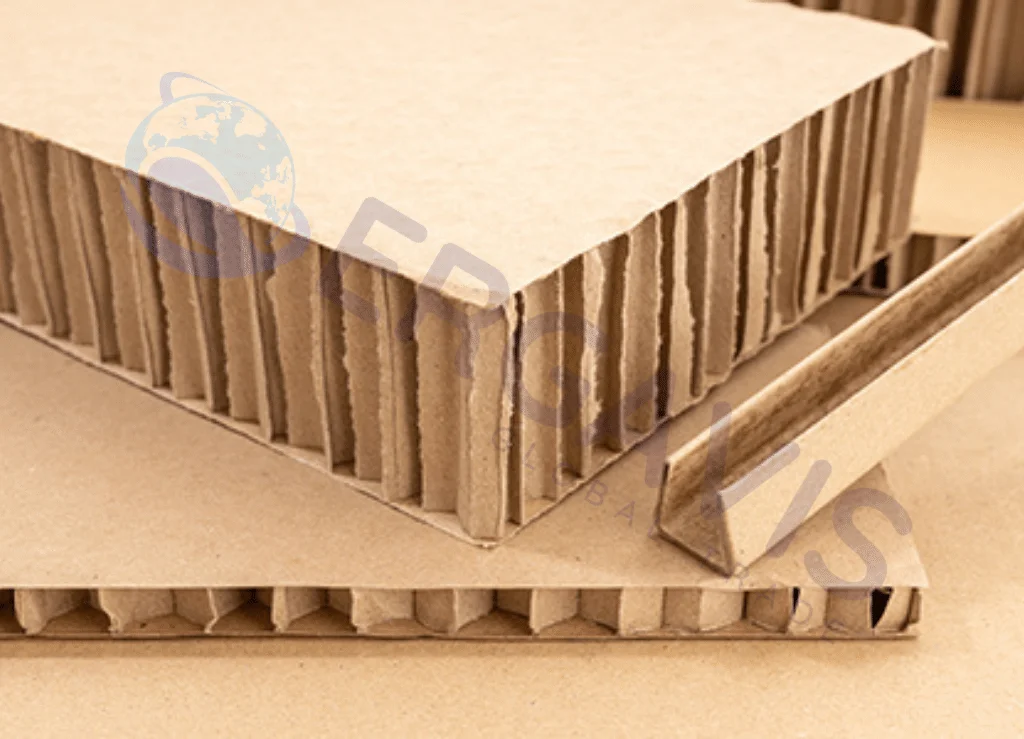

Cardboard cutting (rotary cutting machine, spiral paper cutter), using a spiral blade to cut the paper, the continuous maximum speed can reach more than 300 m/min, and the cutting precision can reach plus or minus 1 mm.